Ward-Leonard control system: Theory and demonstration

- Details

- Published: Thursday, 11 June 2015 13:42

When choosing the main motor for large scale electromechanical systems, two are the main candidate solutions: The AC induction motor and the DC induction motor. In most cases, the AC motor is selected, because of its simplicity, lower price and higher reliability. However, there are cases where the DC machine is preferred and those are where the precision of the speed control is crucial. Since the speed and torque outputs of the DC motor are linear, the control algorithm is a lot simpler. The main objectives of power electronics drives for induction motors are to provide similar control capacity compared to DC motors.

The Ward-Leonard control system is the best solution to have a very smooth speed control for the full range of the DC motor. Nowadays similar results can be achieved using power electronics converters and those drives have gradually replaced older Ward-Leonard systems. Typically, to control the speed of a DC motor either the voltage of the armature or the current of the field coil. While the control of the field coil current has higher efficiency (when not using power electronics) the speed range is limited, as the armature current cannot exceed the nominal value. On the other hand, as the armature current value is a lot higher than the field coil current, the regulation of this current with resistive devices will lead to major power loss. The armature voltage regulation can be provided through a voltage divider or using a resistor connected in series. Due to the advances in the area of power electronics, nowadays it can also be provided using a thyristor 2 or 6 pulse bridge or using an AC/DC power supply.

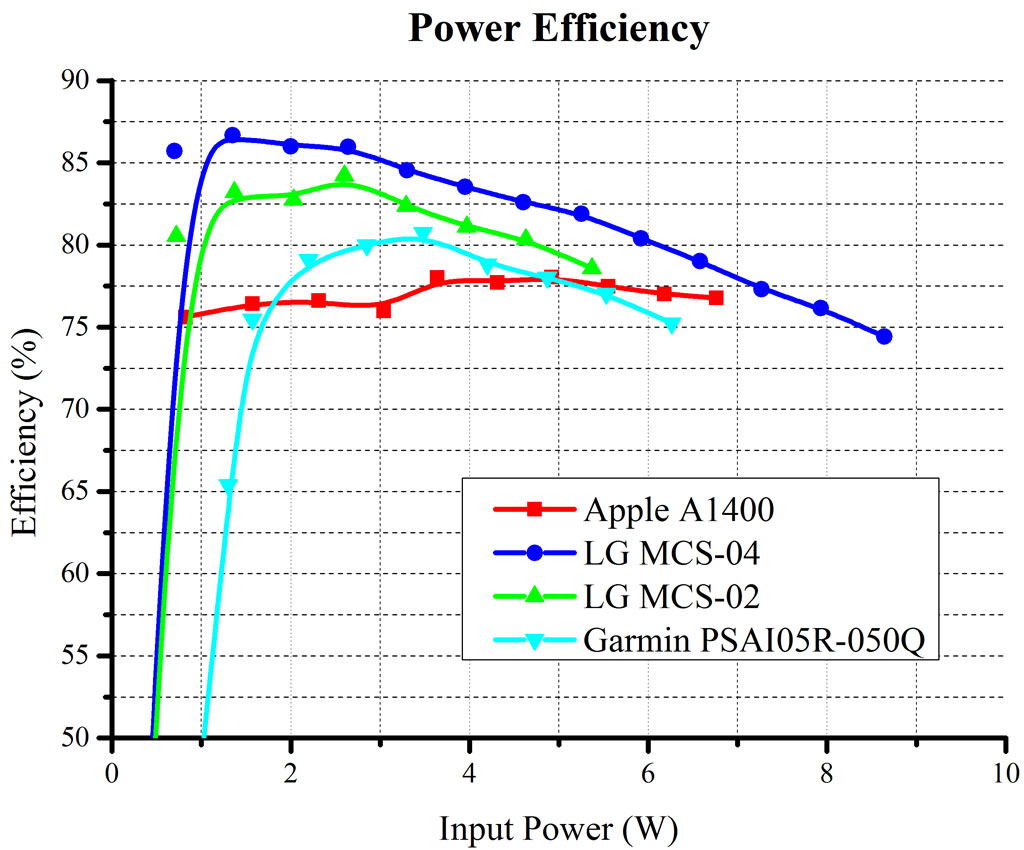

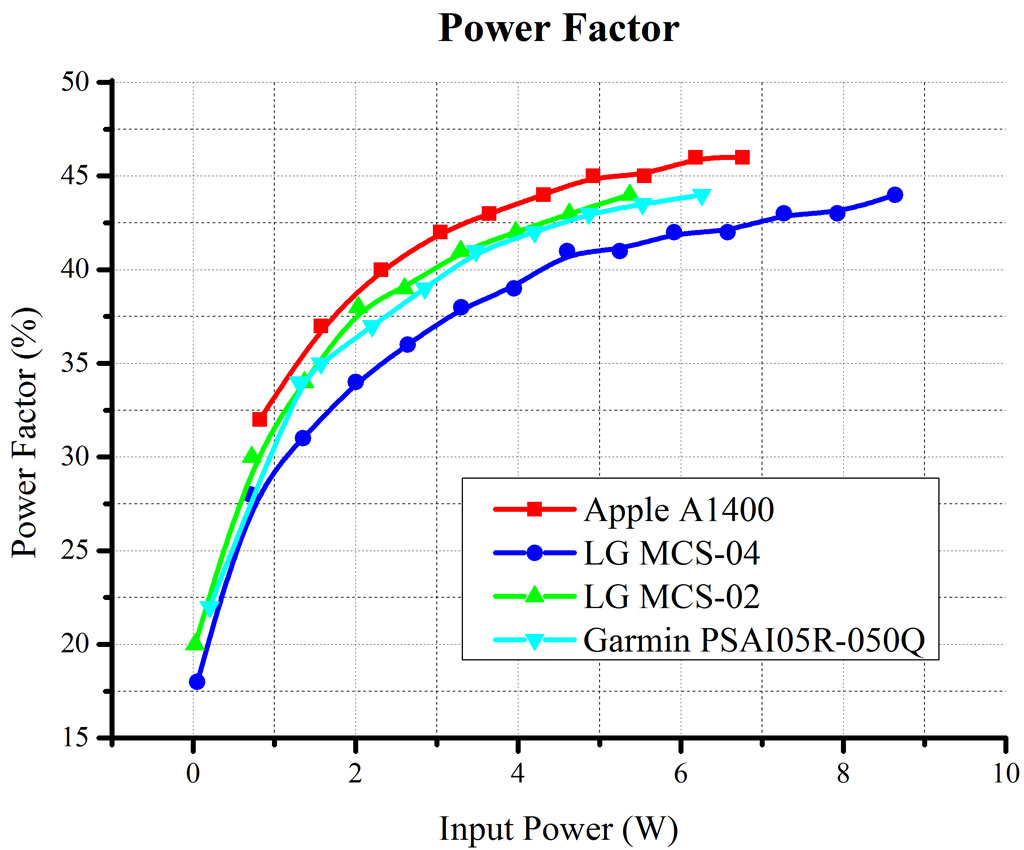

The Ward-Leonard control system provides a DC voltage to the armature that can be adjusted. This voltage is provided by a DC generator. As a result, it can vary from zero to the nominal value of the DC motor, providing a wide range of speed control. The output voltage of a DC generator is mainly a function of the rotor speed as well as its field coil current. So, in the Ward-Leonard system, the speed is kept almost constant and the field current is adjusted using a voltage divider. By adjusting the field current of the DC generator, the armature voltage of the DC motor is adjusted, controlling in the end the rotor speed. Finally, a motor is needed to rotate the DC generator. The type of the motor is irrelevant so it can be a DC motor, an AC induction motor or even an internal combustion or steam engine. The use of such a system with an internal combustion engine was described in Ward Leonard's patent application in 1903. Typical applications of the Ward-Leonard control systems are elevators and radars where the speed as well as position need to be precise. With the advances of SCRs in the 1980s, thyristor bridges started to replace those systems. The thyristor bridges, while being a lot more power efficient, small and cost-effective have extremely low power factor. Those bridges are being replaced with PFC converters with IGBTs or drives with induction motors.

The following figure shows the control system schematic. The main DC motor is machine 3. The field coil is powered by a DC current supply (diode 6 pulse bridge) and the current is at its nominal value. Machine 2, which is the DC generator supplies the voltage to the DC motor armature. The field current varies from zero to its nominal value and is controlled by a DC power supply, or simply by a voltage divider from the DC source. Machine 1 is an induction motor which rotates the DC generator. The rotor speed is almost constant (there is a small variation depending on the load, however this can be counterbalanced by adjusting the voltage divider for the field current.

A common issue of the induction machine is the very high value of the inrush current. That is why a soft starter is usually applied, either using a star-delta topology or more frequently using a power electronics converter. In the following video, the operation of the star-delta topology is shown.

Finally, a laboratory Ward Leonard Control system is shown in the following video. The main DC motor is the front left (which makes the front right machine the load).

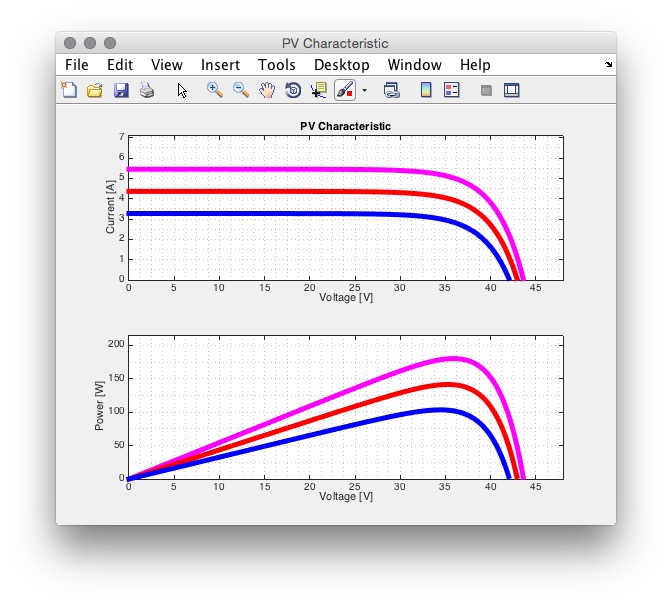

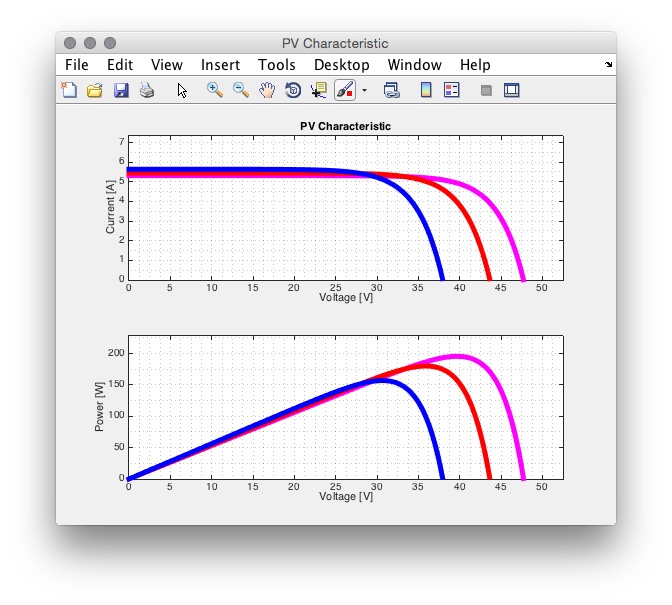

The full project of the Khouzam equations on MATLAB can be found on my

The full project of the Khouzam equations on MATLAB can be found on my